How to Calibrate Your Spreader & Understand Accurate Application Rates

Created March 29, 2023

It’s important to get to know your spreader before you start your salting journey. There are lots of variables to test and play with to find the perfect setting for your preferred material and distinct weather conditions

Why Should You Calibrate?

In order to price your services correctly, you need to know how much material you are using. On average, we put down about 3-5 times more salt than needed because we are just guessing. Adding too much salt will not melt ice any faster and even causes more issues. Over salting can cause damage to surrounding landscape, like flowers and grass, and when used around entryways, can cause damage to door frames or flooring when tracked inside. Save material and calibrate your spreader at the beginning of the season to set yourself up for success.

Test & Understand Your Equipment

To begin the calibration process, you need to experiment and test your equipment. If you do this once at the beginning of the season, you can apply the results to other spreaders in your fleet. Calibration is figuring out the pounds per second your chain conveyor system is distributing.

One Way to Calculate Application Rate

To begin, with the spinner detached, run the spreader for 1 minute at each setting. Dump the material into a tub or storage container.

Then, weigh the container to determine how much salt came out at each setting. For example, if the material weighed 100lbs, then the calculation would be 100/60 = 1.6 lbs/s. If you test and weigh all the settings, then you know the flow rate for each setting which can be used in the formula below to determine application rate.

User Variables

- (X) Spread Patter Width = ____ft (8 to 40ft)

- (Y) Vehicle Speed = ____mph

- (Z) Chain Conveyor Flow = ____lbs/s (0.5 to 3.9 lbs/s)

Conversion Factors

- (A) Distance = 5280 SqFt/Mile

- (B) Time = 0.01667 hr/min

- (C) Area = 43560 SqFt/Acre

- (D) Time = 60 s/min

Calculations

- (E) Spread Coverage = X * Y * A * B = ____ SqFt/Min

- (F) Spread Coverage = C / E = ____ min/Acre

- Spread Coverage Rate = Z * D * F = ____ Lb/Acre

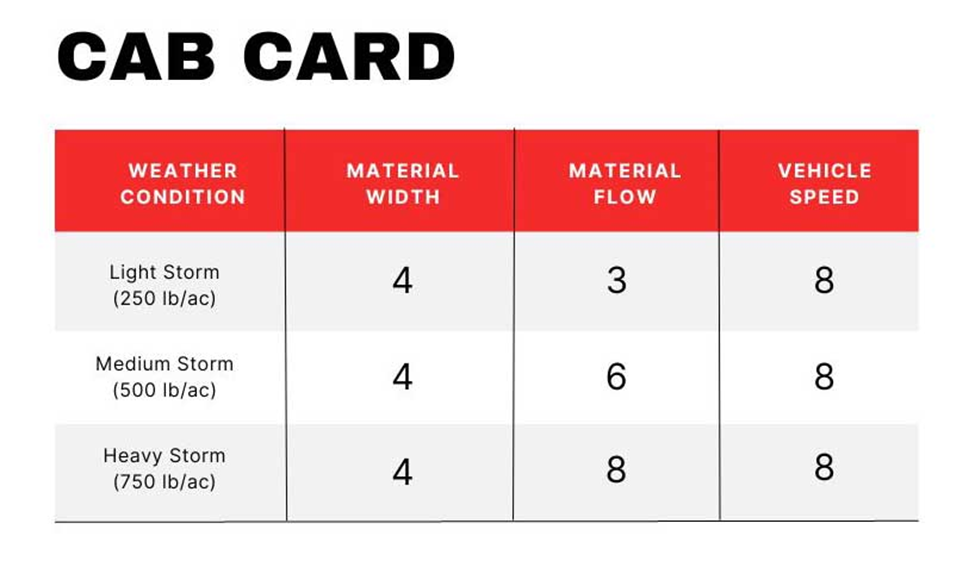

Depending on results, create a cab card that reflects the correct material width, material flow, and vehicle speed based on different weather conditions.

Here is an example of suggested settings for salt application:

There Isn’t One Single Solution

Storms are unpredictable so there isn’t one single solution. Calibrate and experiment with different settings on your hopper before the season starts to be prepared when the snow starts falling.

Tip: The setting on your hopper will vary depending on the type of material you use. For salt, you just want enough to melt the ice. For sand or dirt, you need enough material to cover the surface and create a layer over the ice for traction.

Advantages of Pre-wet Salt

Different de-icing materials can be better for certain situations. Using pre-wet salt has several benefits that allow it to work better and faster in extreme cold temperatures. Pre-wetting salt “activates” the material to accelerate ice melting and the pre-wet granules bounce less when hitting the pavement for greater control and less waste. Studies have also proven that application rates can be reduced by up to 30% when pre-wetting salt with liquids.

Find Local Resources

Find helpful guidance and recommendations for your state from the Department of Transportation and local organizations. Wisconsin Salt Wise is a great place to start. They have information on winter maintenance strategies and an application calculator to determine recommended application rates.

You may be interested in these related articles: