Chain or Auger Spreader? How to Choose the Right Material Feed System

Created October 11, 2021

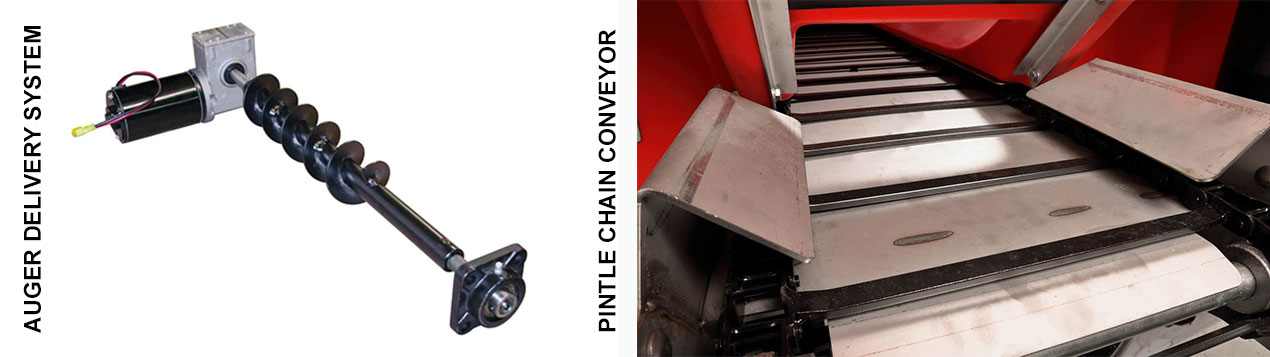

If you’re shopping for a new hopper spreader, you may be trying to decide between a pintle chain or auger delivery system. Whichever you choose, it’s important to first understand the key differences between the two feed systems before you buy. Here’s a quick guide from WESTERN® to keep you informed.

Feed System Differentiation

The biggest difference between a pintle chain and auger delivery system comes down to one thing: engineering. It’s all about how the material is fed to the spinner, which is dependent on material type and can greatly impact performance.

- Auger systems consistently spiral the material out of the hopper and deliver an even feed to the spinner. Augers have fewer moving parts, which typically translates to fewer repairs but that is completely dependent on how well you maintain your equipment.

- Pintle chain systems consist of a number of components that comprise a larger conveyor system. The feed gate opens a door where it pushes the material to the discharge chute and drops down to the spinner assembly.

Spreading Material Compatibility

The first question to ask when making any type of spreader decision is “what type of material am I using?” Salt and sand are totally different from one another and that’s perhaps the biggest factor in choosing the right spreader for your specific needs. Here’s why you may want one versus the other:

Auger + Salt: Auger systems are best for free-flowing materials like bulk salt at a slow, steady flow rate. Salt is used in densely populated cities on highways and metropolitan roads where the taxpayer pool is high and safe travel is expected—even during the middle of a storm. Once salt is exposed to moisture, it has a chemical reaction and starts to activate, melting ice to keep roads safer.

Chain + Sand: Smaller towns and villages in rural areas and remote routes tend to spread sand due to cost and sourcing. This is where a pintle chain system is usually recommend because they are built to handle heavier materials, including sand and other natural materials from the area. These materials can help with traction, although there is no chemical reaction to melt the ice.

Material Output & Pattern

When choosing the right material feed system, you need to understand the material output and how that impacts pattern and performance. Contractors typically put down 150 – 750 lbs of salt per acre and 500 – 2,000 lbs of sand per acre. That’s about three times the amount of sand needed compared to salt, which is why different delivery systems are designed to meet those needs.

- Auger: An auger improves material output and pattern with an even flow of material delivered to the spinner. Salt needs to be distributed evenly in order for the chemical reaction to work properly, which is why the auger delivery system is preferred when deicing.

- Chain: A chain conveyor is like a Swiss army knife and can work for both sand and salt. The feed gate typically opens to 8” tall but most contractors set it at 2-3” when using salt so they don’t waste material and over salt the property. When spreading sand and natural materials, it’s best to expand the feed gate opening to allow for more material flow. Since a lot of sand is needed for traction, you want to spread a lot of material at once and a chain delivery system is intended for that.

TIP: WESTERN offers an inverted V for specific spreader models to help keep sufficient material weight off of the conveyor, ensuring a smooth startup and consistent flow of material.

Hopper or Tailgate Spreader

Beyond the material and maintenance, you’ll also want to consider what kind of spreader you’re looking to use. Large hopper spreaders, like the WESTERN Striker® and Tornado™ tend to have the pintle chain because of the larger volume and the ability to move more material. On the other hand, the smaller tailgate spreaders such as the PRO FLO™ 525 & 900 usually have an auger to guide the material down to the chute.

The Deciding Factor

The decision might end up being as simple as your application and what your vehicle can handle. It’s important to know the difference between the pintle chain and auger delivery systems to fully understand which system is right for you. Knowing about the inner workings of your ice control equipment will help you make smart decisions and ensure you’re using the machine properly.

Ice control is an important step in winter cleanup and can be a lucrative part of your business if you’re equipped and informed. As they say, you plow for show, but you spread for dough. If you make the right investment in your ice control equipment, it can pay big dividends for you in the long run.

For more information on which type of spreader is best for your specific setup, contact your local WESTERN dealer for pricing and availability.

Other Articles You May Be Interested In: